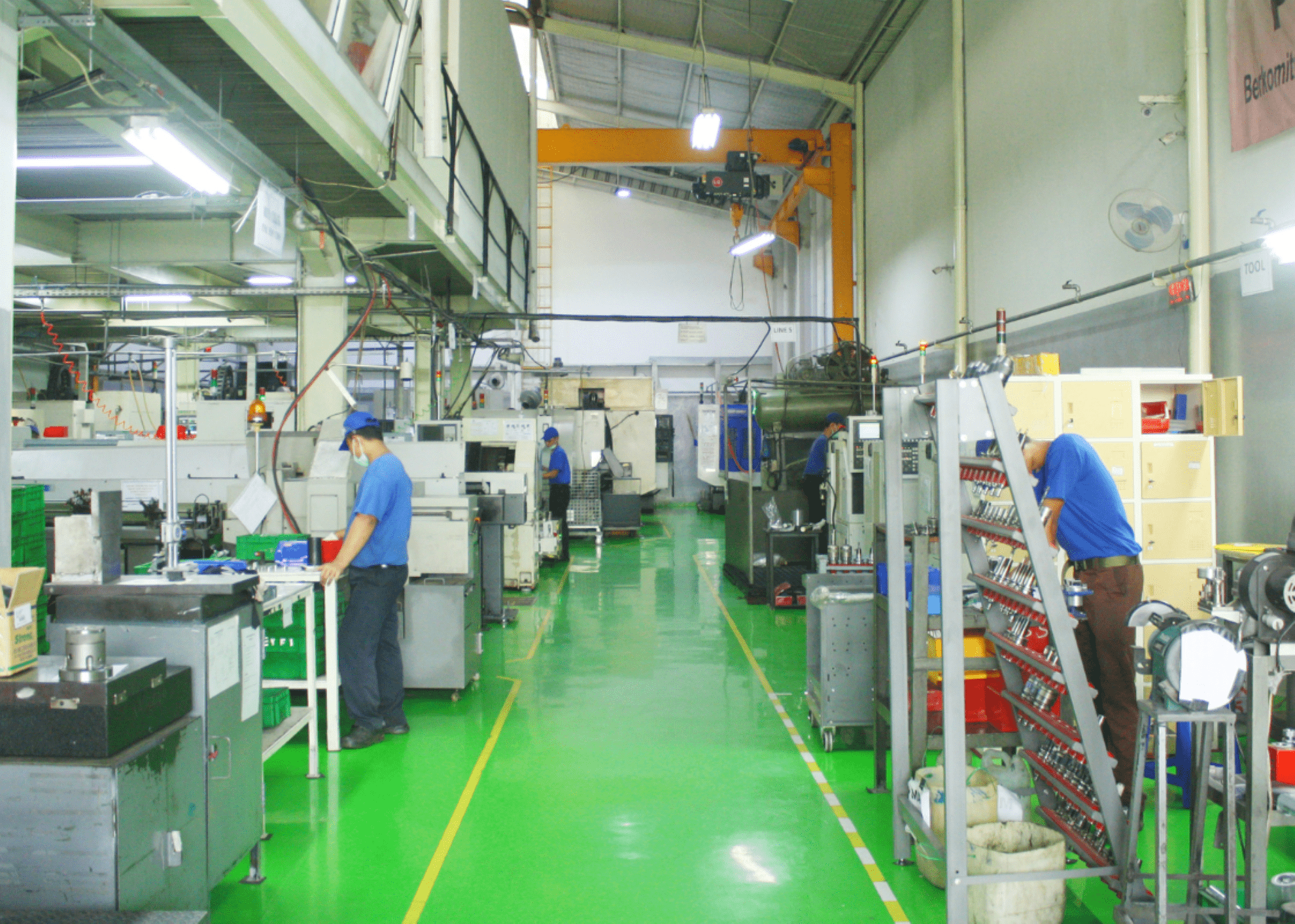

Company Facility

Working Area

3 WORKSHOPS

Currently, we have 3 workshops that we use to run the production of our company. We allocate our resources according to our customers demands.

Quality Control Devices

Profile Projector VPP-300

Used to measure the dimensions of small, complex parts by projecting an enlarged image of the part onto a screen

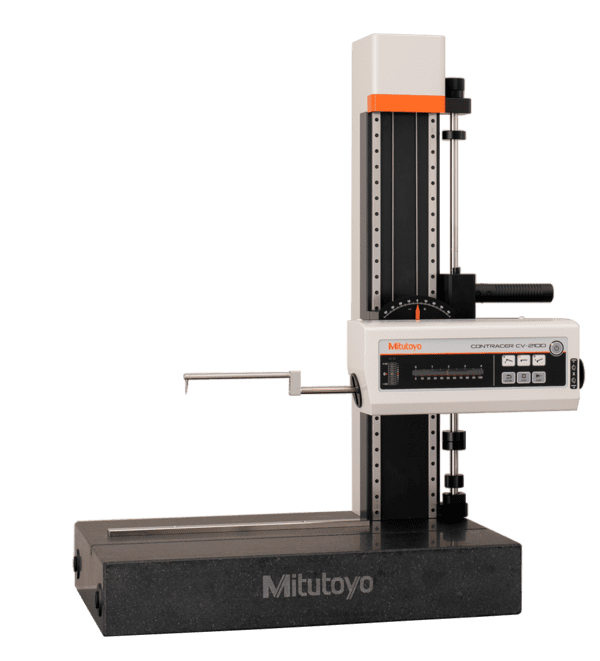

Contracer CV-2100

Used to measure the contours and surface profiles of components. It accurately measure the angles, radii, and complex curves of a component

Surfcom Touch 50

Used to measure the texture and roughness of surfaces, providing data that is essential for ensuring the quality of machined or finished surfaces

Mitutoyo SJ-210

Used to measure surface texture and roughness with high precision. Its portability allows measurements in various locations

Company Capabilities

CNC Machining Center

Campro CPV - 750

(848x429)

Quantity: 1 Unit

Wele CV - 1060

(1150x600)

Quantity: 1 Unit

Priminer MINI

(650x300)

Quantity: 1 Unit

Quaser MV184C

(1200x600)

Quantity: 2 Unit

CNC Lathe

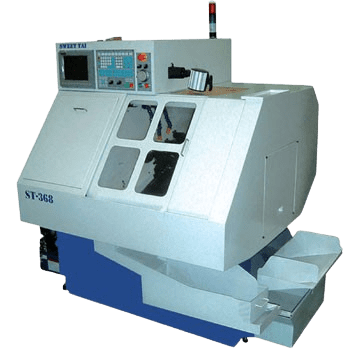

Sweet Thai

Lathe 5"

Quantity: 3 Unit

Takisawa TC-100

Lathe 6"

Quantity: 6 Unit

SAMSUNG

Lathe 6"

Quantity: 1 Unit

LA

Lathe 10"

Quantity: 2 Unit

Swiss type CNC Lathe

Citizen A12

Quantity: 2 Unit

Citizen A20

Quantity: 1 Unit

Citizen L20

Quantity: 1 Unit

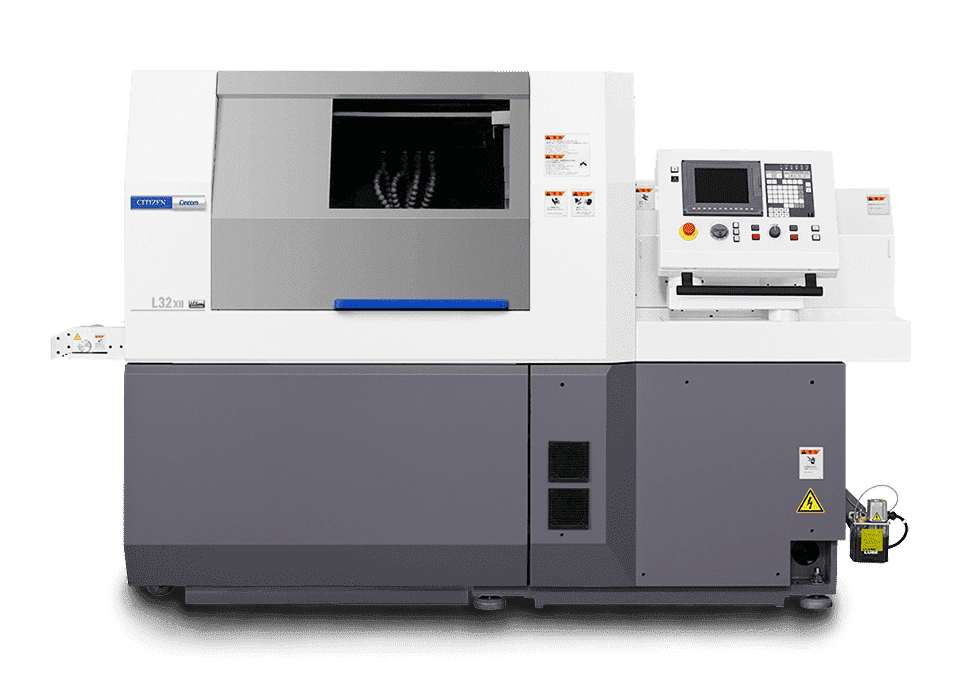

Citizen L32

Quantity: 1 Unit

Drilling & Tapping Center

Brother

Quantity: 6 Unit

Fanuc Robodrill

Quantity: 1 Unit

Other Machining Division

Wire Cut

Quantity: 3 Unit

Automatic Rolling Machine

Quantity: 1 Unit

Surface Grinding

Quantity: 1 Unit

CNC EDM

Quantity: 1 Unit

Centerless Grinding

Quantity: 1 Unit

Bandsaw Cosen 320

Quantity: 1 Unit

Manual Lathe

Quantity: 1 Unit

Manual Milling POLO

Quantity: 1 Unit