Our Divisions

Custom Solution

Abrasives

Metalworking Oil

Cutting Tools

Cutting Machines

Custom Solution

Our custom solution consist of 2 divisions:

- Dies & Jigs

- Automotive Parts

Dies and Jigs are custom made tools that are used to help the process of metalworking. While dies are used to cut and/or form materials to a desired shape or profile, jigs are used to control the location and/or motion of parts or other tools.

With the machines that we currently have, not only dies & jigs, we are also able to make automotive parts. Our capabilities allow us to make small parts with a minimum diameter of 0.5mm up to 1000mm.

Product History List

Abrasives

Abrasives are materials that are used to shape or finish a workpiece through worning a part of the workpiece using friction. While finishing a workpiee, abrasives are often used to roughen the material in order to create different types of polished finishes. Selindo Group mainly focuses on the production of grindstones.

A grinding stone (grindstone) is a type of abrasive shaped similar to a wheel and often used for various grinding (abrasive cutting) and abrasive machining process. The wheel can be made from different types of coarse materials which affect the roughness of the finished product. Those materials then get pressed and bonded together to form a solid circular shape with various profiles and cross section that are different for each intended use.

Our Products

Surface Grinding Stones

Internal Grinding Stones

Resinoid Grinding Stones

Cylindrical Grinding Stones

Mounted Grinding Stones

Mounted Rubber Grinding Stones

Mounted Internal Grinding Stones

Centerless Grinding Stones

Regulating Wheel

Metal Working Oil

Metalworking Fluid (MWF) is the name given to a range of oils and other liquids that are used to cool and/or lubricate metal workpiece when they are being machined, ground, milled, etc. MWF reduce the heat and friction between the cutting tool and the workpiece, and help preven burning and smoking. Applying MWF also helps improve the quality of the workpiece by continuously removing the fines, chips, and sward from the tool being used and the surface of the workpiece. (Swarf are the small pieces of metal from a workpiece by a cutting tool)

Our Products

Gear Oil

Application:

- Gear Lubrication

Hydraulic Oil

Application:

- Anti Wear Hydraulic Fluid

- Fire Resistance Hydraulic Fluid

Sliding Oil

Application:

- Sliding Lubrication for Machine Tool and Other Equipment

Rust Preventive Oil

Application:

- Antirust Oil

Forming Oil

Application:

- Alumunium Fin Punching Fluid

- Bending, Piercing, and Deep Drawing

Water Soluble Cutting Oil

Application:

- Cutting and Grinding of Steel and Ferous Metal

- Cutting and Grinding with longer live service

- Special Oil for Grinding with Excellent Biostatic Additive

Neat Cutting Oil

Application:

- Cutting Oil

- Non Chloric Cutting

Cleaner

Application:

- Water Soluble Cleaner

- Solven Base Cleaner

Heat Transfer Oil

Application:

- Heat Transfer Oil

Other Speciality Oil

Application:

- Cosmetic Grade

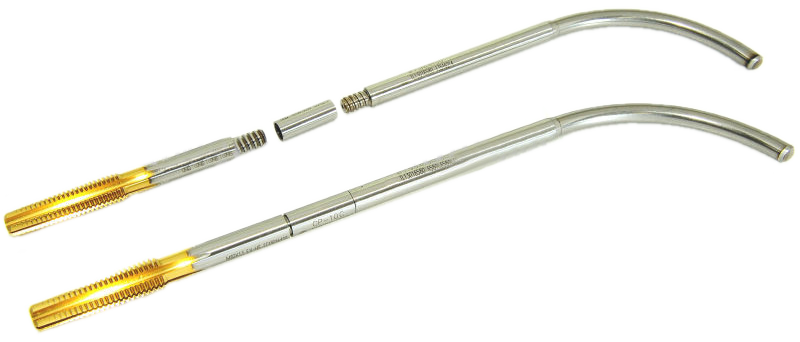

Cutting Tools

Cutting tools are instruments used to remove material from a workpiece through a variety of machining processes such as drilling, milling, turning, and grinding. These tools are designed to precisely shape or finish materials, typically metals, by means of controlled material removal. These tools are essential in various metalworking applications for producing detailed and high-precision components

Our Products

Drills & Taps

Drills

Taps

Step Drills

Bent Taps

Endmills & Reamer

Flat End

Ball End

Corner Radius End

Indexable Insert & Holder

Milling

Turning

Drill

Other Tools

Carbide Rotary Burrs

Services

Regrind & Recoating

Cutting Machine

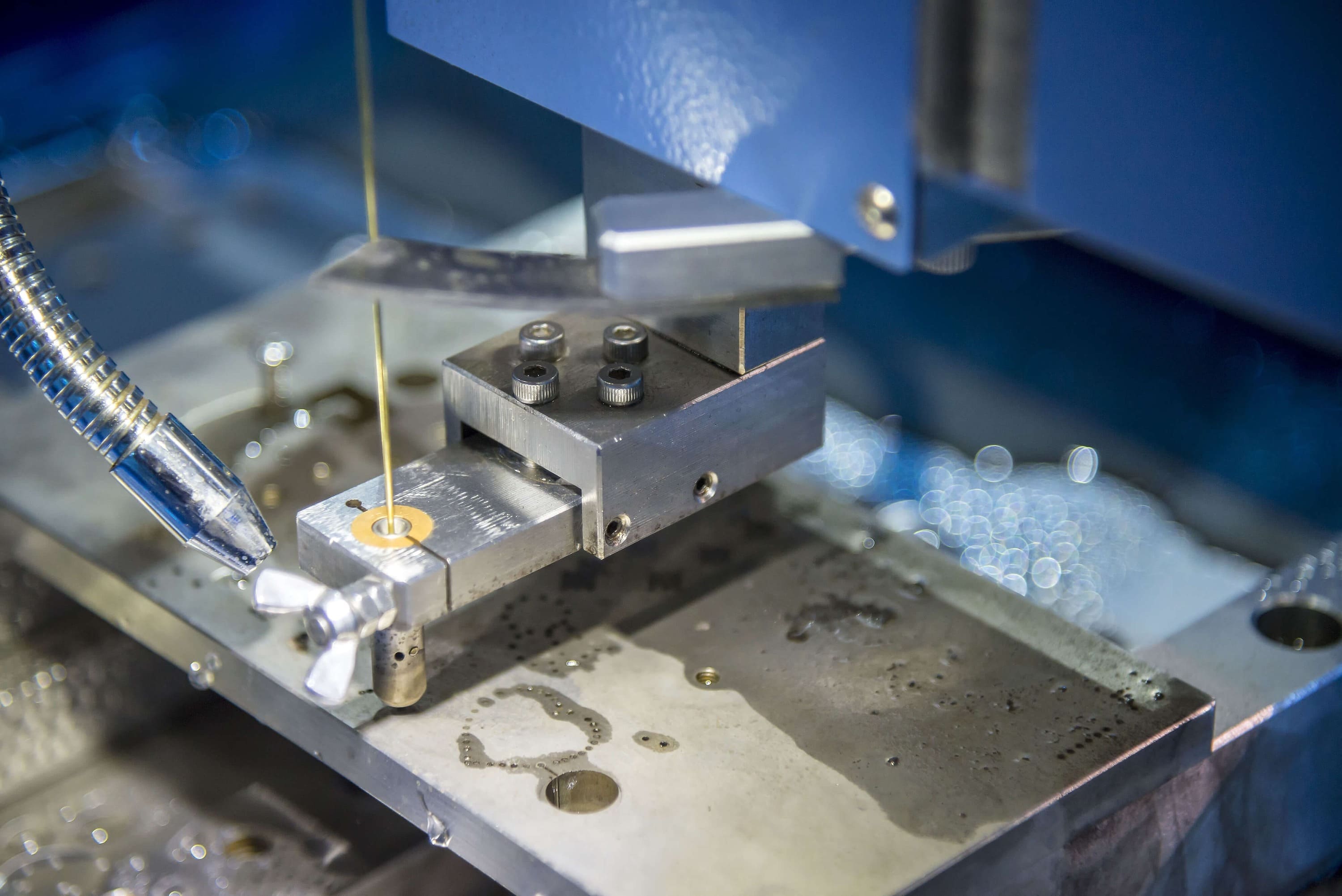

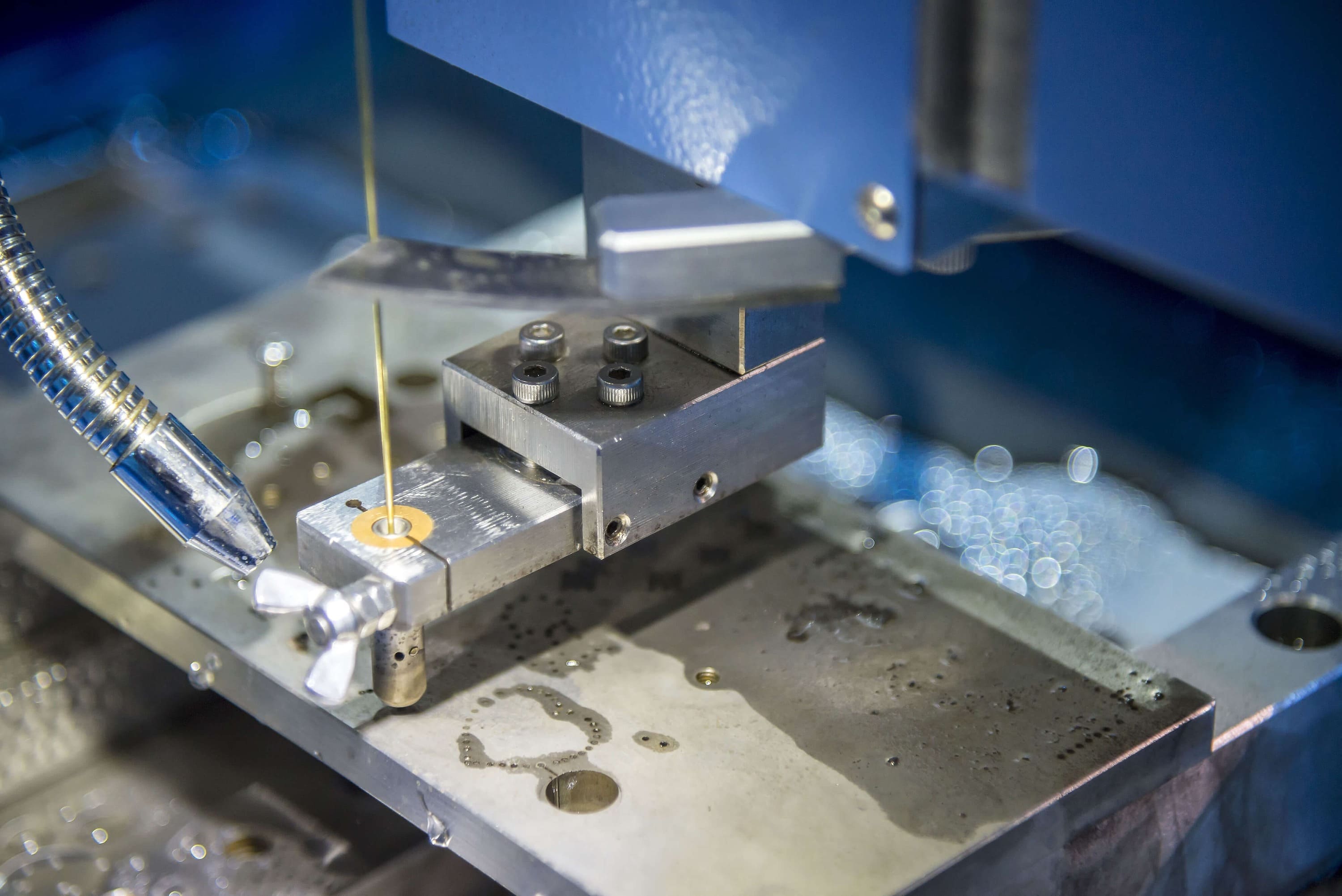

Cutting machine is a device used to cut various materials into specific shapes or sizes with precision. Selindo Group mainly focuses on selling EDM Machines (Electrical Discharge Machining), a specialized manufacturing tool that uses electrical discharges (sparks) to remove materials from a workpiece. It is commonly used to cut hard metals or materials that are difficult to shape with traditional cutting tools.

In manufacturing industry, machines are differentiated into 2 category, conventional and non-conventional machines. Conventional machines include lathes, mill, drill machines. While non-conventional machines consist of wire cut machines.

Our Products

CNC Wire EDM Machine

Description:

Cutting machine that uses molybdenum wire together with Electric Discharge Machining (EDM) process to chip away small amount of material until the desired shape is obtained.

Super Drill EDM Machine

Description:

Cutting machine that uses brass rod together with Electric Discharge Machining (EDM) process to create precise small to micro holes in the material.

EDM Machine

Description:

Cutting machine that uses block-shaped copper electrode together with Electric Discharge Machining (EDM) process to chip away layers on the materials similar to the shape of the electrode.