Welcome to

Your One Stop

Selindo Group

Your One Stop

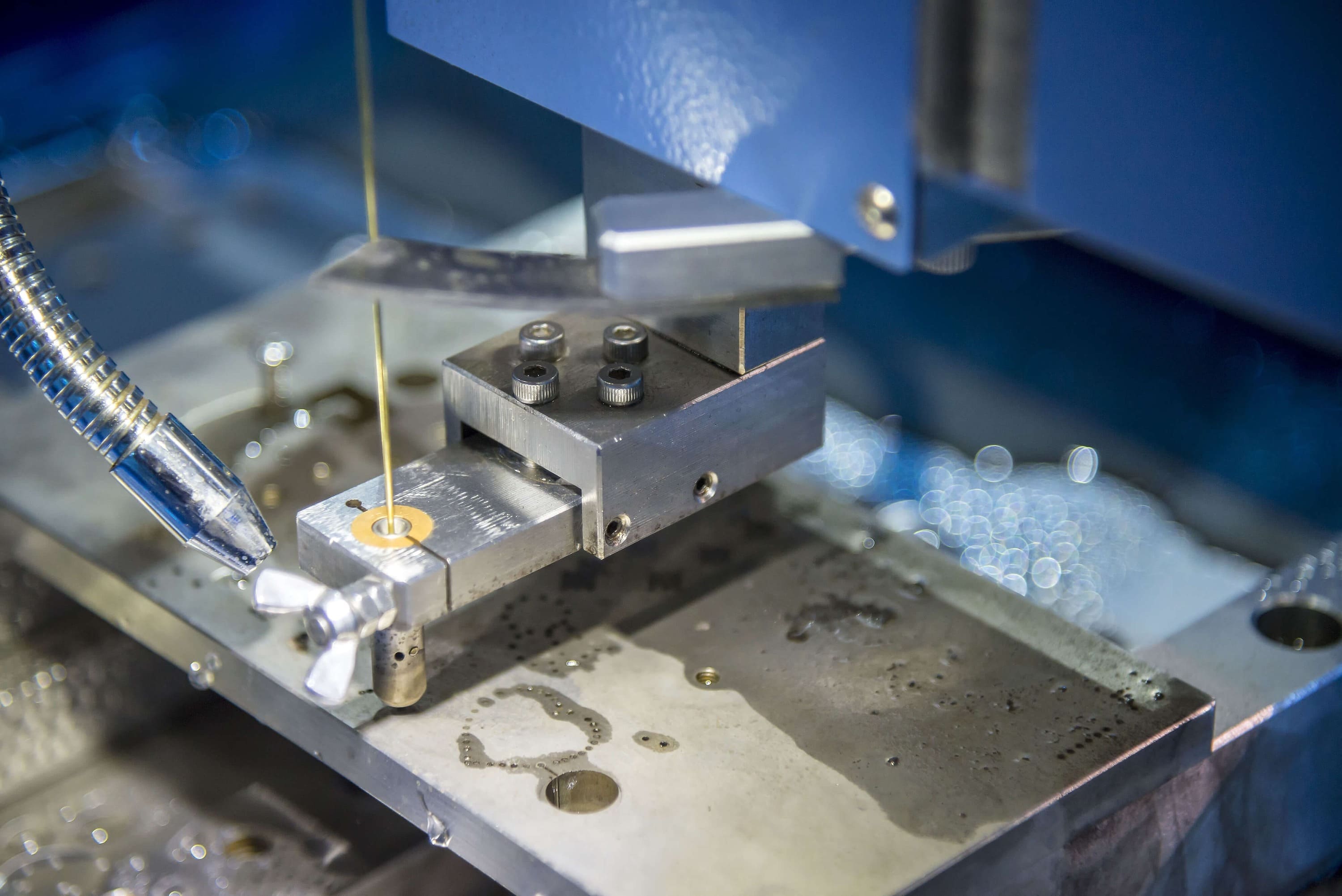

Metalworking Solution

We provide high quality products for each of your metalworking needs

Our Advantages

Contact Info

- sales@suryaselindo.co.id

- Taman Tekno Blok K2/11

+62 758-712-97

About Selindo Group

What we do

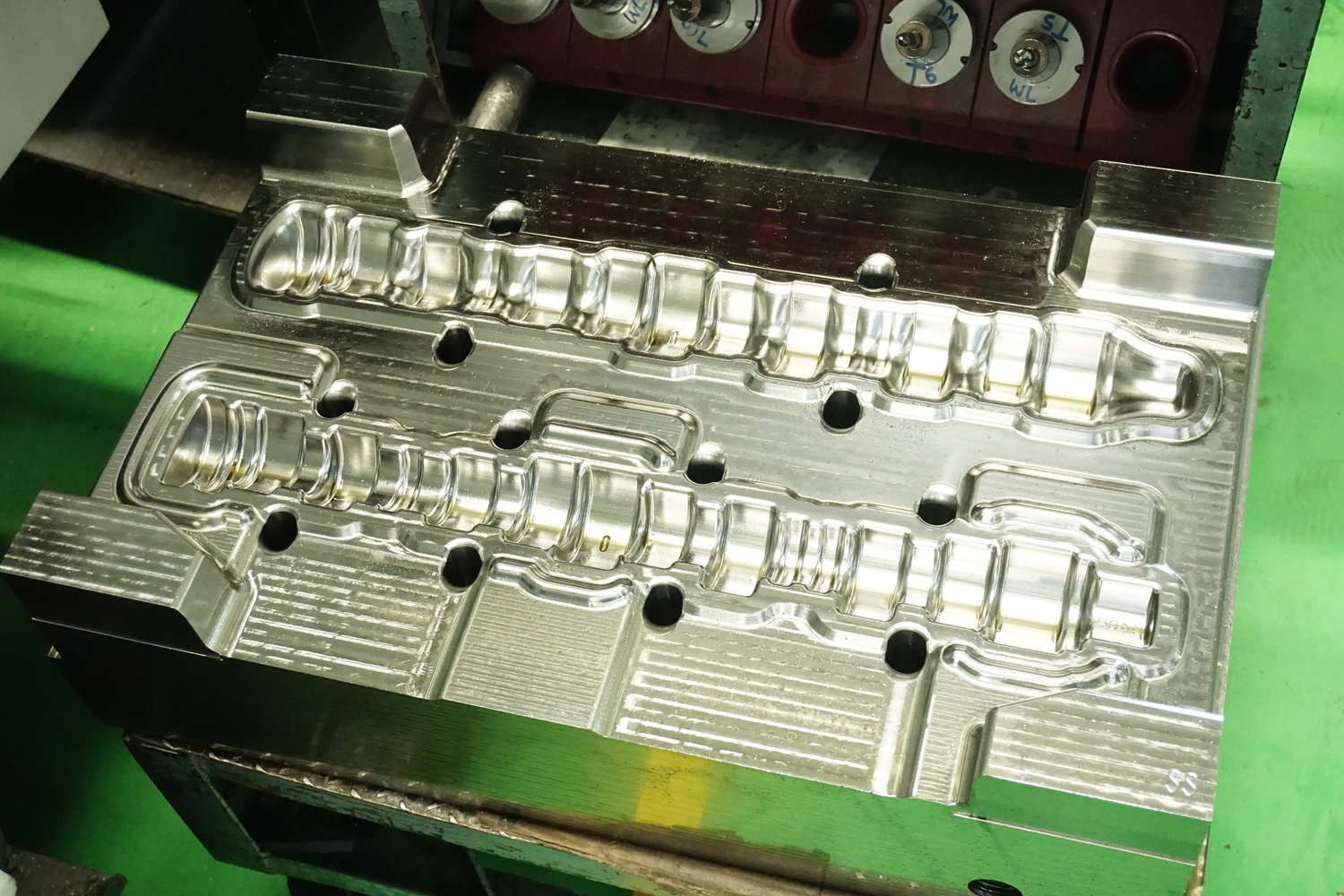

Selindo Group is a company that sell, supply, and produce metalworking tools. In addition to that, we provide a service to manufacture made-to-order metal pieces.

Read More About UsWhat we offer

Product Divisions

Abrasives

Metalworking Oils

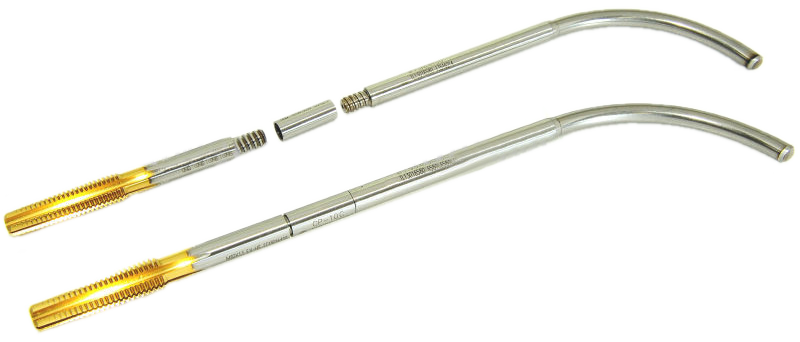

Cutting Tools

Cutting Machines

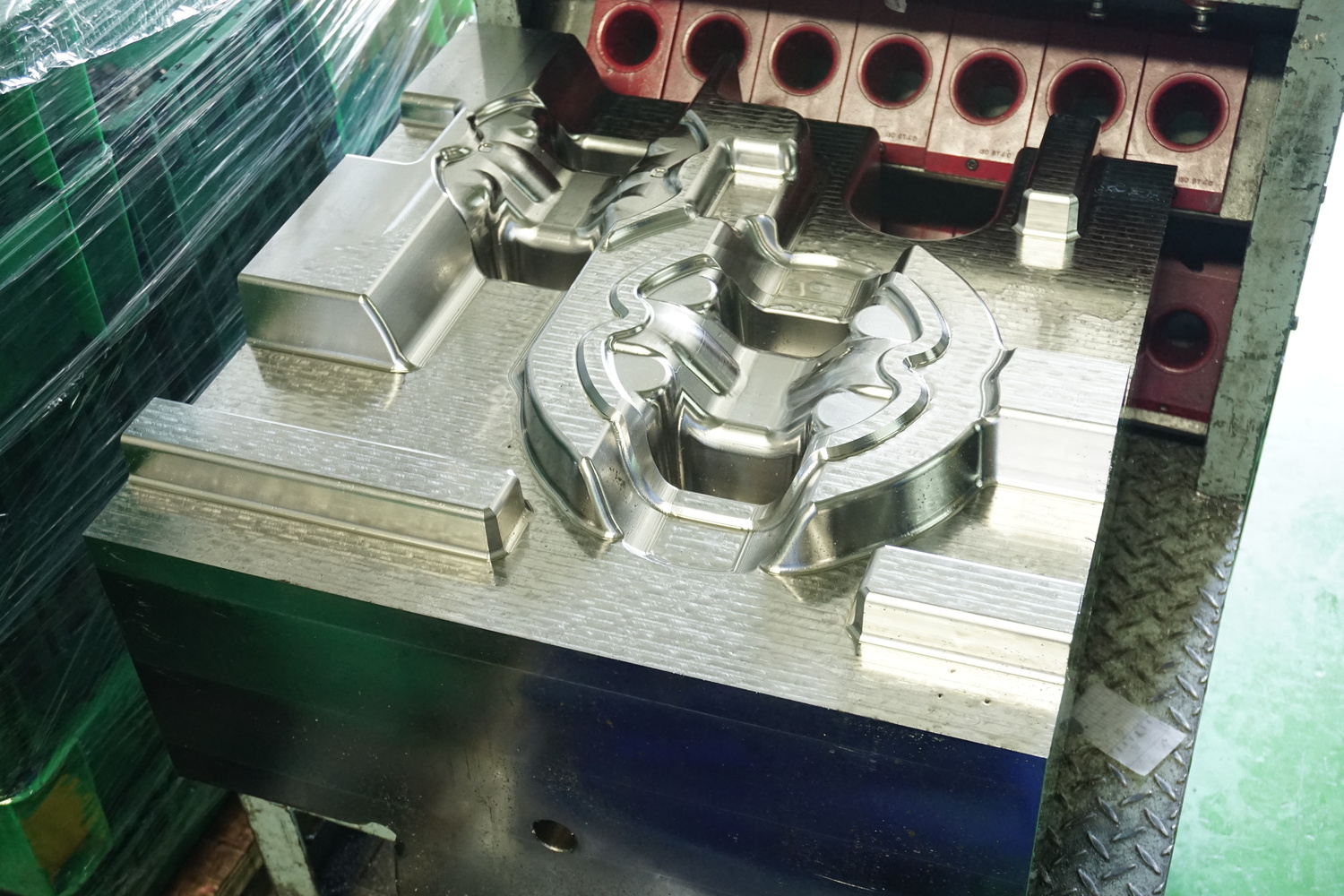

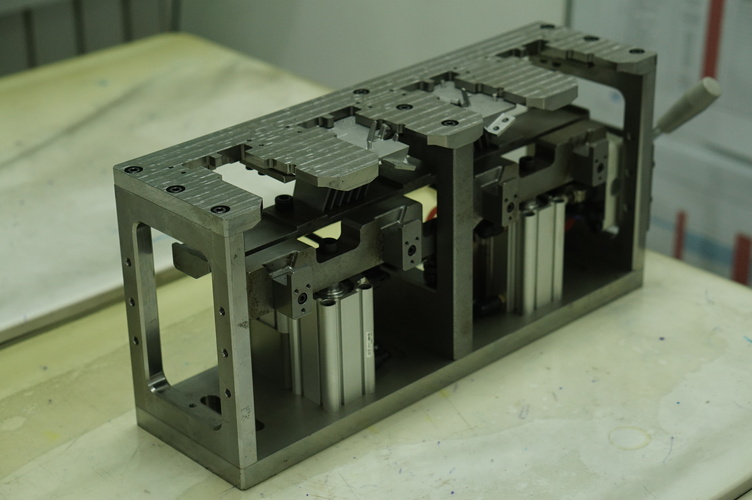

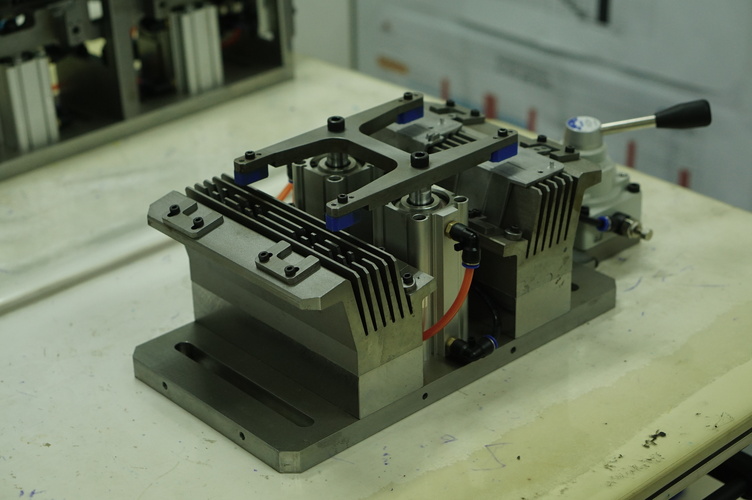

Custom Made Solution

- 1 Provide us with the finished product or the products blueprint

- 2 We'll make a sample from the agreed design and necessary adjustments

- 3 Once the product is to your liking then we'll mass produce it.

Why Choose Us?

What makes our service excellent:

- ISO 9001:2015 Certified Company by TÜV SÜD

- Exceptional quality check technologies

- 400+ projects delivered safely to our Clients

- 190+ clients satisfied with our service

- Well Equiped with 19 years of experienced

Contact Us

Let our products help your metalworking process now

Get in touch with us through:

WhatsApp - 021 758-712-97

Email - sales@suryaselindo.co.id